WHAT IS A RAINSCREEN?

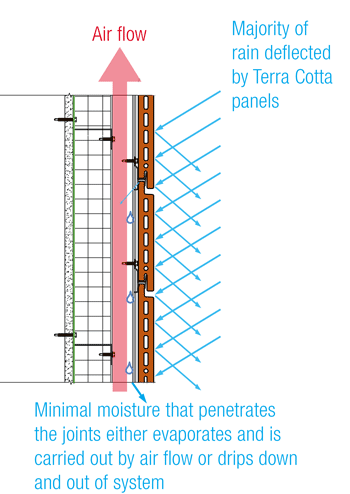

Terreal North America’s terracotta rainscreen consists of an outer panel, ventilated cavity, and an inner skin. A rainscreen system is pressure equalized – meaning the joints are open to allow instantaneous pressure equalization in driving rain conditions. Pressure inside the cavity is equal to pressure outside, thus precipitation has no inclination to be driven into the cavity. Majority of water is deflected off the outside face – allowing any penetrating water to be disposed of through drainage.

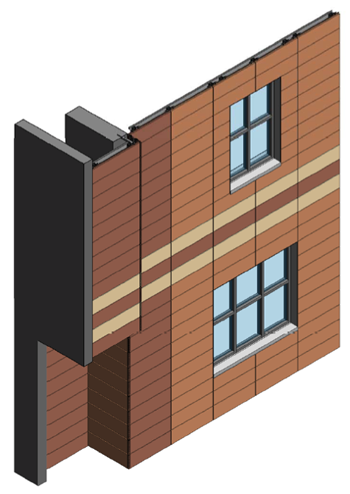

Terracotta Rainscreen Assembly: Panels Installed

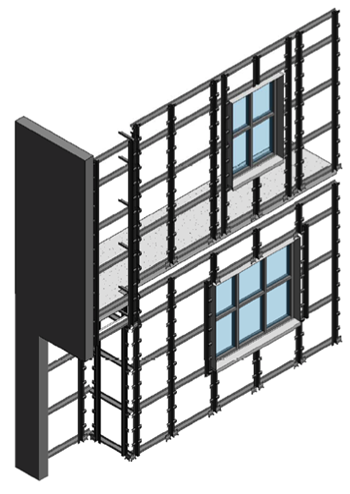

Terracotta Rainscreen Assembly: Support Framing Installed

How Rainscreen works

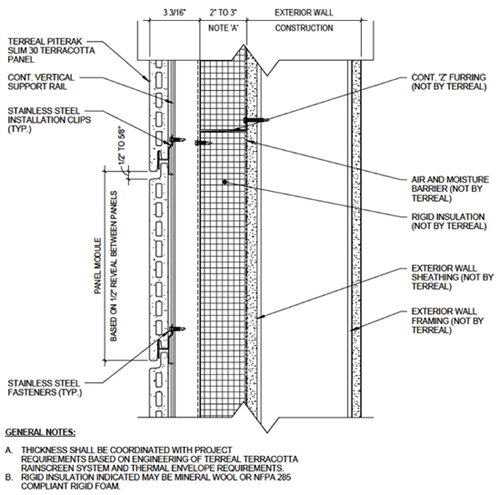

Typical Terracotta Wall Assembly Section

THE TERRACOTTA RAINSCREEN ADVANTAGE

Improves structure and life expectancy

- Improves upon failure in conventional sealed systems.

- Protects the wall system from direct rain, wind, and weather with it’s additional skin.

- Prevents water penetration into the wall due to better ventilation.

- Less pressure / wind let into the primary wall – acting as a shield.

- Equalized pressure leads to lower water absorption.

Energy savings

- Thermal benefits lead to energy savings.

- Air space reduces heat bridge, meaning less heat transfer / lower cooling costs.

- Added airspace helps prevent condensation.

- Better comfort inside the building – heated thoroughly in winter and cool freshness in the summer.

Low maintenance costs

- Terracotta panels are high impact resistant (double skin products have highest Q4 rating in France for impact) – panels do not easily break.

- Broken tiles can be replaced without removing system.

- Terracotta panels are color permanent and do not fade, no painting required.

- Concealing critical building joints from UV rays and weather elements requires less re-pointing and re-caulking – equaling cost savings.

Ease of installation

- Simple system with ability to be installed many different trades.

- Can be installed year-round in all weather conditions due to no use of mortar.

- Some systems are lightweight and can be installed from man-lifts, preventing the need of scaffolding.

- Lightweight clay panels can be installed quicker than traditional heavy systems – such as brick/mortar, stone, granite, and marble.

Weather Tight

- Extra protection of facade and structure.

- Traditional cladding leaks because many joints are exposed – leading to greater pressure on the exterior facade and forcing water into the structure.

- Helps avoid thermal shock, resulting in less structure cracking.

- Maintenance-free building system – no re-caulking.

- Eliminates and decreases many of the joints found in traditional cladding methods, reducing potential leaks.

- Less water passage and cracking + pressure equalization and constant ventilation = Water Tight Structure.